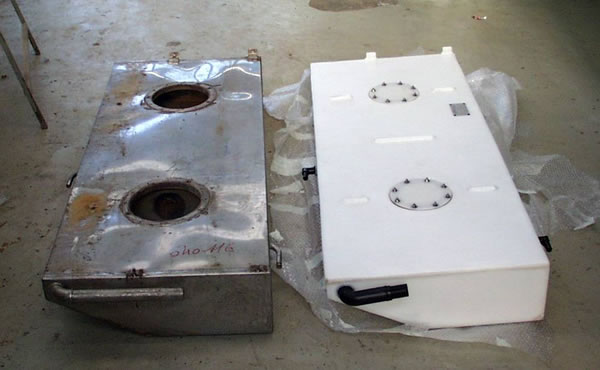

YachtWORKS proudly introduces a High density Polyethylene (HDPE) tank system that overcomes the persistent corrosion problems of stainless steel and mechanical failure of flexible bags. This system has been developed by Vela Ltd. which endeavours to build HDPE recipients since 1999.

The HDPE will not corrode and ensures an almost condensation free environment for the fuel and provides clean taste free water for the galley. A substantial part of our work is replacement tanks for boats previosly fitted with mechanically unreliable flexible bags or stainless and aluminium tanks with electrolysis problems.

All our tanks are built from 8-12mm thick HDPE and are pressure tested to 0.2 bar which is equivalent to a fill point 2 metres above the tank. Higher pressures can be achieved and would have to be specified when placing an order. Standart specification would include baffles placed aproximately every 300mm which protrude through the top of the tank and then welded, this is to prevent the top of the tank from lifting when under pressure. The inspection hatches, supplied as a regular option, are bolted on with fully encapsulated stainless steel bolts and sealed with neoprene gaskets. Our usual practice is to supply tanks with welded female thread sockets of gas pipe thread [1]. Different sockets, Metric, Special and Oversize, can be supplied for customers to fit their own fittings if need be.

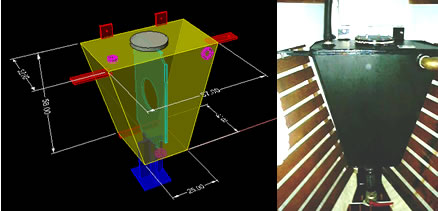

The tanks all have some sort of internal baffling to our specifications for two main reasons, firstly , to introduce rigidity to the tank, and secondly, to limit movement of contents.The baffles have a six inch diameter hole to allow access from the inspection hatch (if fitted) to the adjacent compartment to facilitate cleaning and inspection.

Tanks built from rigid HDPE lend themselves to one-off production because there are no expensive mould tools to build. Tanks are of all welded construction and built either to the customer size and shape or to yachtWORKS measurements. In any case the tanks are to yachtWORKS specification. HDPE cannot be curved severely for one-off applications but multifaceted shapes normally solve most design problems.Complicated shapes are obviosly more expensive than simple right angled ones.

YachtWORKS offers with Vela Tanks the custom and production boat builder the ideal solution to the problem of storing diesel fuel and fresh, gray and waste water. We will be pleased to help with any design problems and efficient service from our service point in Bodrum.

At yachtWORKS we believe in providing our customers with „no compromise“, high quality products and equipment, backed by a fast, friendly and professional service. YachtWORKS also supplies a comprehensive selection of fittings, gauges and senders custom made to your requirements.

[one_half]

[/one_half]

[/one_half]

[one_half_last]

[/one_half_last]

[/one_half_last]

The Production range at yachtWORKS

-

Tanks for fresh water, diesel fuel, gray water and waste water.

-

Collectors with strainer and pump for shower water and for the sink drain.

-

Shower trays

-

Watertight liners for chain lockers.

-

Watertight liners for cockpit lockers, lazarettes etc.

-

Raw water strainers for main engines, generators and similar.

-

Ice boxes, frezeres and fridges.

-

Mosquito nets for portholes.

-

Almost any engineering product of your imagination.

Design Considerations

If you should decide to provide us with the tank dimensions, here are some guidelines:

1. Make sure the tank can be installed into the space it is designed for, i.e. will it go through locker door/companion way. Make sure the tank can be easily removed.

2. Don’t make the tank a too tight fit. The material, like all welded materials, distorts slightly during manufacture.

3. Make sure the inlet, outlet and vent pipes can be pushed onto the spigots without kinking and that jubilee clips can be tightened.

4. Avoid curved tanks and wide shallow tanks placed athwartships.

5. Give careful consideration to fastening tanks down.

6. Fix tank down with one or more of the following methods. They are all acceptable but are listed in order of preference.

I. Box in with 12 mm marine ply.

II. Set into position with self rise foam.

III. Strap down using strong webbing and fastening buckles or stainless steel straps.

When supplying information for us to quote against, please supply clear dimensioned drawings including the following information:

1. Maximum outside dimensions of tank including templates of any relevant angles, shaped ends etc. If sending drawings then please mark right angled faces, if any, on irregular shaped tanks.

2. Positions and outside diameters of all inlet, outlet and vent spigots for water tanks, external diameters of copper or nylon tube for diesel tanks.

3. Indicate the maximum hydraulic head the tank is likely to sustain, i.e. distance from bottom of tank to deck filler.

Waste Holding Tanks

Design Considerations

1. Try to arrange the bottom of the tank to slope towards the suction outlet pipe.

2. Try to position the inlet so that solids do not need to migrate across the bottom of the tank.

3. Vent the tank with a minimum of 1/2″ bore non-collapsable hose. Avoid water traps in the vent line.

4. Try to avoid long pipe runs.

5. Empty tank before it is full so that solids do not enter vent pipe.

How Big?

If sink and shower waste is also being contained the holding tank must be substantially larger. Used with care, a shower will require about 12 litres each time it is used. Obviously both sink and shower waste quantities depend entirely on how the facilities are used, as well as frequency of use. The size of a holding tank is entirely dependant on the berth/size of the boat and the anticipated duration between pump-outs. A holding tank can never be too large but can be inconveniently small. Restriction on size depends on available space for installation and effect on the boats trim. The following formula will provide an approximate guide to the minimum size of the tank which is acceptable:

Berths x days between pump-out x Y = Litres capacity of tank

For recirculating systems factor Y = 2

For fresh water flush systems Y = 10

The above assumes low water use toilets are being used and does not allow for sink or shower.

A brief guide to Marine Sanitation

Portapotties

Portapotties require no plumbing; they may or may not have a reservoir for flush water. Bowl contents drain by gravity into a removable tank which is carried off the boat and dumped, although some larger models can be fitted for pumpout. Very little water is used in the operation. Capacity is 10 – 25 litres.

The Heads [2] (Marine Toilet)

Manual pump heads are just what the name implies: you pump water in and out of the bowl manually. They are designed to use „raw“ (sea, lake or river) water for flushing. The amount of flush water can be controlled to some extent by how much you pump.. It’s possible to add an electric motor (typically 12v DC current) to some models; the motor simply replaces your arm in activating the pump.

Electric macerating heads are only a little more complex than a manual head. They are typically designed to use raw water. An impeller pump replaces the piston type found in manual heads, and there is also a discharge pump. Between the two is a device called a macerator that is not totally unlike a blender or a garbage disposal, it purees solid waste & paper. Like a garbage disposal, a macerating head needs a lot of water, typically 1 to 3 gallons each time it’s flushed, or it will burn out.

Sanitation Hose

Sanitation hose has long been the subject of a whole lot of debate. Some experts insist that anything less than double walled hose is unacceptable, some even recommend the use of rigid PVC. In fact, the first is an unnecessary expense, the second could be the worst thing you could do.

There have been problems with hose in the past, and there is hose on the market today that is totally unsuitable for sewage and it’s impossible to determine, just by looking, whether a particular white flexible PVC hose is suitable for use in sanitation systems or not. Vela tanks can supply a sanitation grade hose.

Finally, the system including the tank, should be at least nominally rinsed after each pump-out, through the head or back down the deck pump-out with fresh water only.

Routine Maintainance

Never put anything into a marine sanitation system that is not specifically marketed for that purpose. Do not use detergent, washing up liquid or other cleaners, especially cleaning products which contain pine oil, petroleum, or alcohol. Those substances will break down the seals, gaskets, and valves in the system, and will also break down the walls of the hose, causing it to be more susceptible to permeation. Above all, do not pour vegetable oil down the head to „lubricate“ the parts. A layer of oil on the sewage will only seal the contents of the tank, keeping air out of it. Follow manufacturers‘ recommendations for periodic maintenance and lubrication.

At least once every two years, put a complete rebuild kit in your head as part of your regular spring recommissioning; if you lay your boat up every winter, we suggest doing it every year. When seals, gaskets, valves and impellers dry out they become brittle and prone to crack. By replacing them regularly you all but eliminate the possibility that you will have to make emergency repairs to the head. Although it’s impossible to predict someone putting something in the head that’s too large to pass through, a well-sealed pump that’s working to factory specifications can often push a borderline object through that a worn system can’t.”Do not put anything into the head that hasn’t been eaten first!“ Marine toilet paper, if available at all, is a poor solution. Just don’t put anything else in the head.

English

English Turkish

Turkish Русский

Русский